High-Quality Hot-Dip Galvanizing Services

We provide durable, standards-compliant hot-dip galvanizing for structural steel components. With a large-scale facility and advanced equipment, we ensure reliable corrosion protection for projects of any size.

Our Service

Our Galvanizing Services

Hot Dip Galvanizing

We provide professional hot dip galvanizing services for structural steel, industrial components, and fabricated assemblies. By immersing steel in molten zinc, we create a tough, uniform coating that offers long-lasting protection against corrosion, even in harsh outdoor or industrial environments.

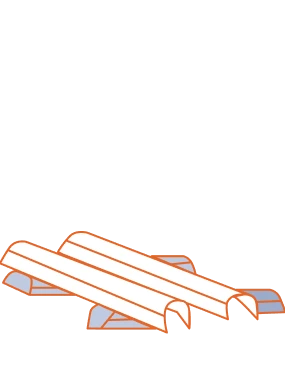

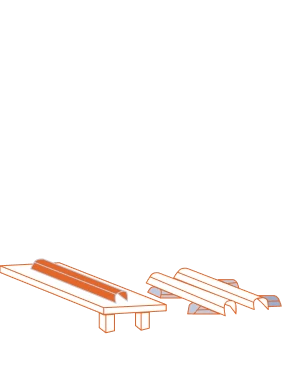

Centrifuge Galvanizing (Spinning)

Our centrifuge galvanizing service is tailored for small, detailed, or threaded components like bolts, nuts, brackets, and fasteners. After dipping in molten zinc, the parts are spun at high speed to remove excess zinc, ensuring clean threads and precise dimensions. This process delivers all the corrosion-resistant benefits of hot dip galvanizing, while preserving the usability of intricate parts.

Hot-Dip Galvanizing Process

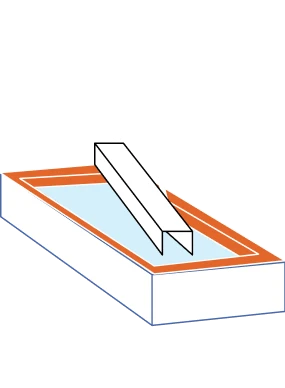

What is Hot-Dip Galvanizing?

Hot dip galvanizing is a highly effective method of corrosion protection where steel is coated with molten zinc. It provides long-term durability by forming a strong, bonded protective layer. Even if the coating is slightly damaged, the surrounding zinc offers sacrificial protection.

Compared to paint or other coatings, it offers lower long-term costs and is ideal for heavy-duty applications like structural steel, walkways, pipes, and reinforcement in concrete.

Degreasing

The steel surface is cleaned to remove oil, grease, and dirt using an alkaline or solvent-based solution, ensuring optimal surface preparation.

Rinsing

After degreasing, the material is rinsed with water to eliminate any remaining chemicals and contaminants.

Pickling

Steel is immersed in a hydrochloric acid solution to remove rust, mill scale, and oxides, exposing clean bare metal.

Rinsing

A second rinse ensures all acid residues are thoroughly washed off to prevent contamination in subsequent steps.

Flux Solution

The cleaned steel is dipped in a zinc ammonium chloride flux solution to prevent oxidation and enhance the bond between zinc and steel during galvanizing.

Drying

Before galvanizing, the material is dried to remove moisture that could cause defects during immersion in molten zinc.

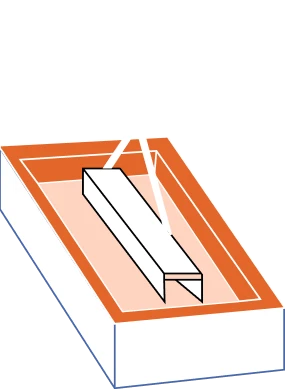

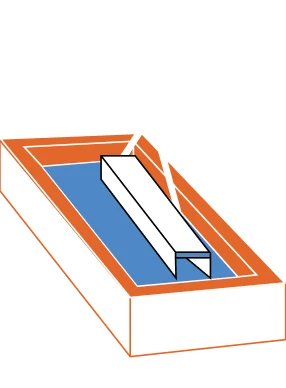

Zinc bath

The dried steel is submerged in a molten zinc bath at approximately 450°C. The zinc metallurgically bonds to the steel, forming a corrosion-resistant coating.

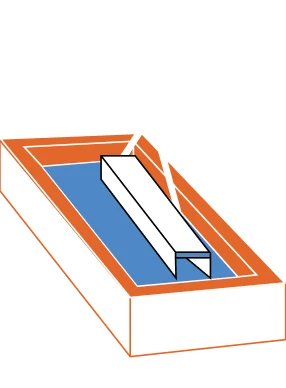

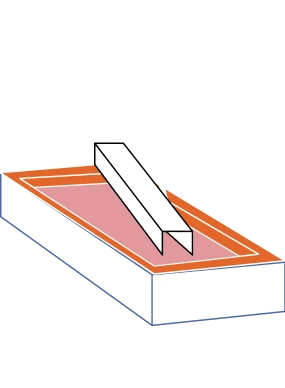

Quenching

Immediately after galvanizing, the steel is rapidly cooled in a water-based quench tank. This step helps stabilize the coating and improve handling efficiency.

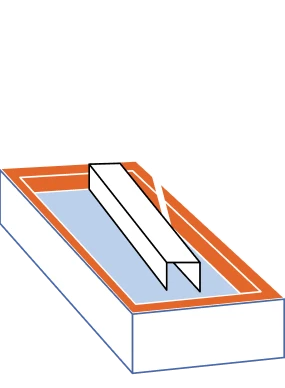

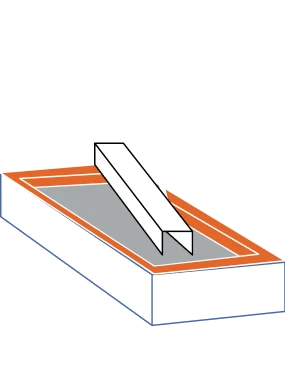

Passivation

After quenching, a passivation treatment is applied to the galvanized surface. This inhibits white rust formation during storage and transportation and enhances the coating’s long-term appearance and performance.

Cooling and Inspection

Final cooling is followed by visual and thickness inspections to ensure the galvanized coating meets international quality standards such as ASTM, BS, or JIS.

We deliver more than services

why choose us

With three decades of experience and industry-certified processes, we deliver consistent galvanizing quality

at scale — trusted by leading contractors, fabricators, and manufacturers across Thailand and beyond.

Situated in the Eastern Economic Corridor (EEC), RGC is ideal for clients with operations in Rayong, Chonburi, and nearby provinces — with direct access to key logistics routes and ports.

Our skilled team and modern facilities ensure corrosion protection that meets international standards, including ISO 9001 and ASTM compliance.

We serve a wide range of sectors — from transmission lines and telecom to automotive, prefab construction, and industrial equipment.

Using 99.995% special high grade zinc and strict process control, we deliver uniform coating performance and long-lasting durability.

Benefit from the stability, reputation, and nationwide network of one of Thailand’s leading industrial groups.

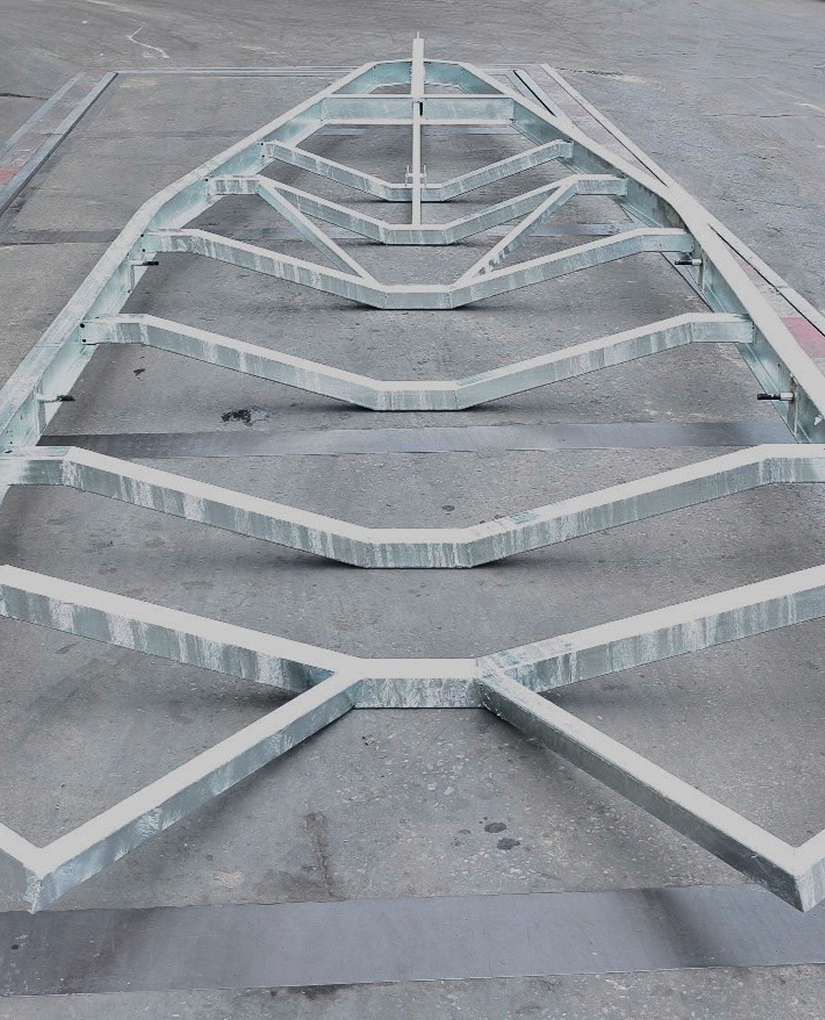

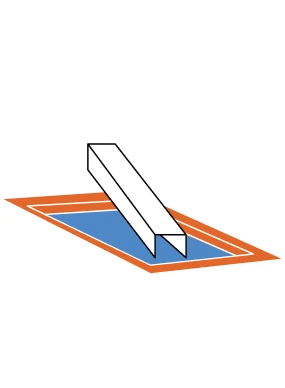

Case Study

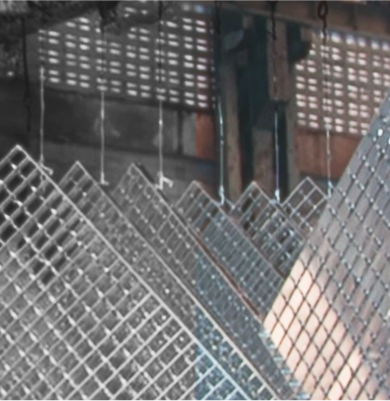

Project Steel,

Extending Lifespan

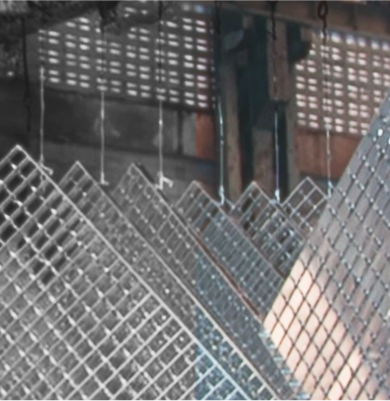

A regional steel fabricator delivered uncoated grating panels for use in a coastal environment. Within weeks, rust had already begun to form. Rayong Galvanizing applied a uniform hot-dip zinc coating that offered over 40 years of corrosion protection in marine conditions.

After galvanizing, the steel gained long-term durability, improved aesthetics, and required no future repainting — reducing lifetime maintenance costs for the client by 60%.

Our service

We specialize in providing durable hot-dip galvanized solutions.

We offer comprehensive hot-dip galvanizing services to protect steel structures against corrosion. Our facilities are equipped with advanced technology to ensure uniform coating, long-term performance, and cost-effective protection for construction, industrial, and infrastructure applications.

FAQ

Answers to Your Questions

We have a base rate, but pricing is

negotiable for bulk orders. The cost is calculated based on the post-galvanizing weight in Baht per kilogram.

American Standards: ASTM A123/A123M, A153/A153M

British Standards: BS 729

International Standards: BS EN ISO 1461

Australian Standards: AS 1214, AS/NZS 4680

Japanese Standards: JIS H8641

German Standards: DIN 50976

With ground finishing, we remove excess zinc drips and wire marks. Without it, the surface remains raw and requires customer-side finishing. Opting out of grinding can result in faster lead time.

Typically 5–7 working days, depending on workload. Smaller quantities may be completed sooner.

Our accounting team will notify you of the total cost before pickup. Payment can be made in cash on delivery or via bank transfer in advance.

Yes, but we’ll first need to review your drawings or photos. Our team can also consult with you on-site if needed.

Saraburi Branch:

- Building 1: 9.0 m (L) x 1.80 m (W) x 3.0 m (D)

- Building 2: 13.5 m x 1.60 m x 2.50 m

- Building 3 (Spinning): 2.0 m x 1.0 m x 1.0 m

Samut Prakan Branch: 13.5 m x 1.60 m x 2.50 m

Rayong Branch: 13.5 m x 1.60 m x 2.50 m

This typically results from high silicon content in the steel combined with high bath temperatures, especially with thicker sections.

Weld joints are incomplete or improperly sealed

The product was not adequately cleaned before galvanizing

We operate 3 branches:

1. Siam Steel Galvanizing (Saraburi)

2. Siam Steel Galvanizing (Samut Prakan)

3. Rayong Galvanizing (Rayong)

Warping is possible due to the 450°C bath temperature, especially for thin or asymmetrical components.

Yes. We provide logistics using 6-wheel side-load trucks, each carrying up to ~5.5 tons per trip. Fees depend on distance, and customers are responsible for loading and unloading.

Smart solutions for all sectors

Built for All Industries

Electrical

Galvanized steel supports critical power and telecom infrastructure such as electrical transmission towers, substation frameworks, cable trays, grounding materials, poles, and telecommunications towers and components — ensuring long-term protection and reliability.

Industrial

In industrial settings, galvanizing protects structural steel, machinery supports, conveyor systems, handrails, and storage racks. Its resistance to chemicals and moisture makes it perfect for factories and processing facilities.

Transportation

Galvanized steel is essential in the transportation sector for its durability and corrosion resistance. Common applications include guardrails, highway sign structures, light poles, and truck/trailer components — ideal for long-term outdoor exposure.

Construction

Galvanized steel is ideal for construction exposed to weather and moisture. It offers long-lasting durability with minimal maintenance — perfect for poles, roofing, structural beams, scaffolding, and coastal structures.

Consumer Applications

Galvanized components are used in everyday products such as metal furniture, gates, fencing, storage units, and bicycle racks — offering lasting performance with minimal upkeep.

Other Industries

Beyond these sectors, our hot-dip galvanizing services extend to agriculture, marine and offshore, mining, water treatment, and many more. Whatever your industry or project, we offer customized galvanizing solutions to meet your specific needs.